In-Space Manufactured Moon Modules

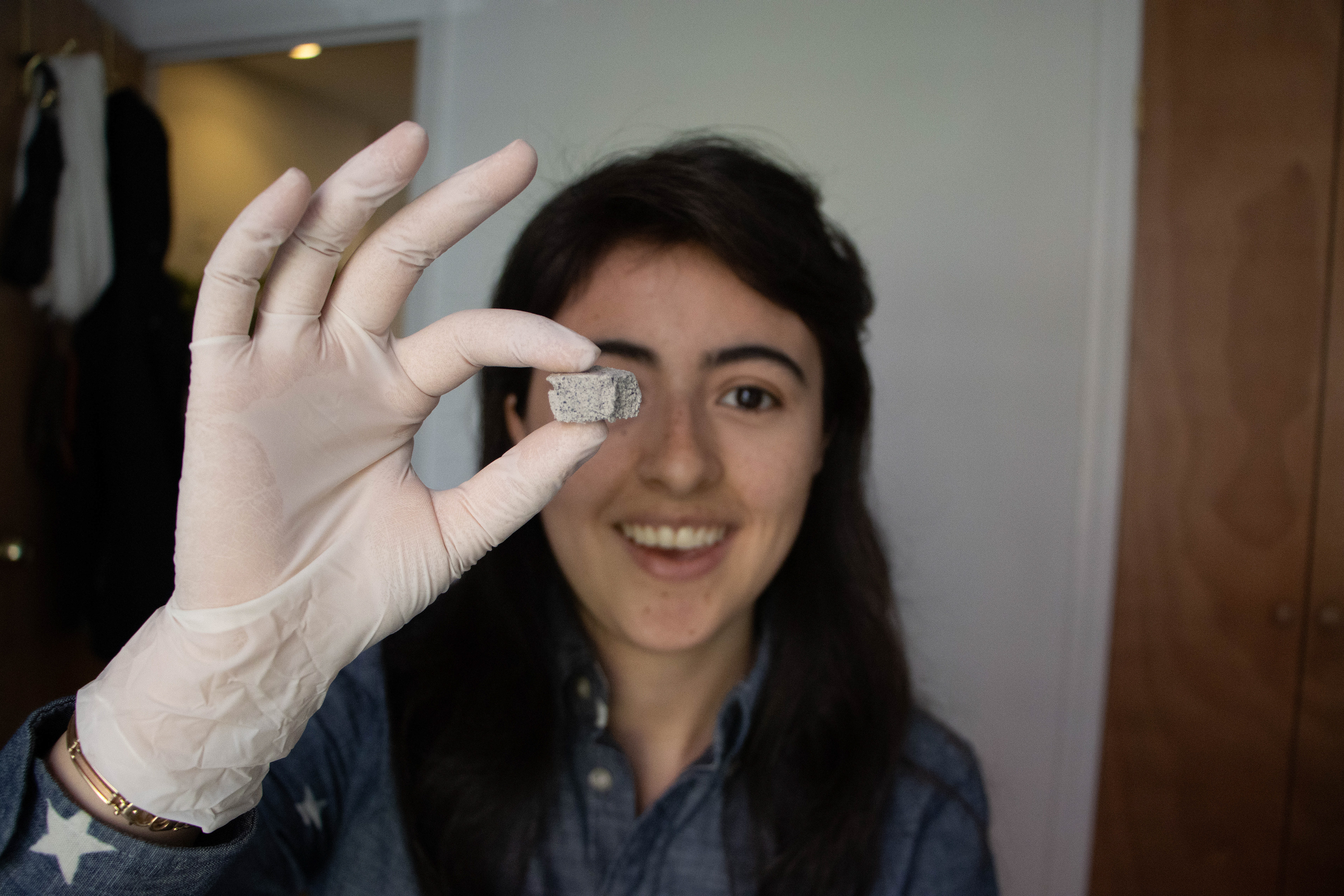

The aerospace industry is imminently sending people to the Moon and Mars, actively pursuing the expansion of human presence in the solar system. The goal is not only to visit, but to eventually inhabit these new frontiers. Creating constructed environments in these unexplored lands will bring significant design challenges. Moon regolith is the abundant layer of the fragmental unconsolidated mantle that covers most of the lunar surface. In this project, we examined the feasibility of using compounds found readily on the Moon to develop a new type of concrete, specifically with sodium-based compounds as a binding cement and the raw regolith as the aggregate; furthermore, the integration of paraffin is also investigated as a waterproofing mechanism. Considering the limitations of space travel, we then present the Moon Module, a versatile (in-situ manufactured) outcome for this novel type of concrete. The capability to use this building material for radiation shielding, environmental endurance, thermal insulation, sealability, structural stiffness, etc. would represent a significant step towards extraterrestrial architecture construction and expansion of human presence.

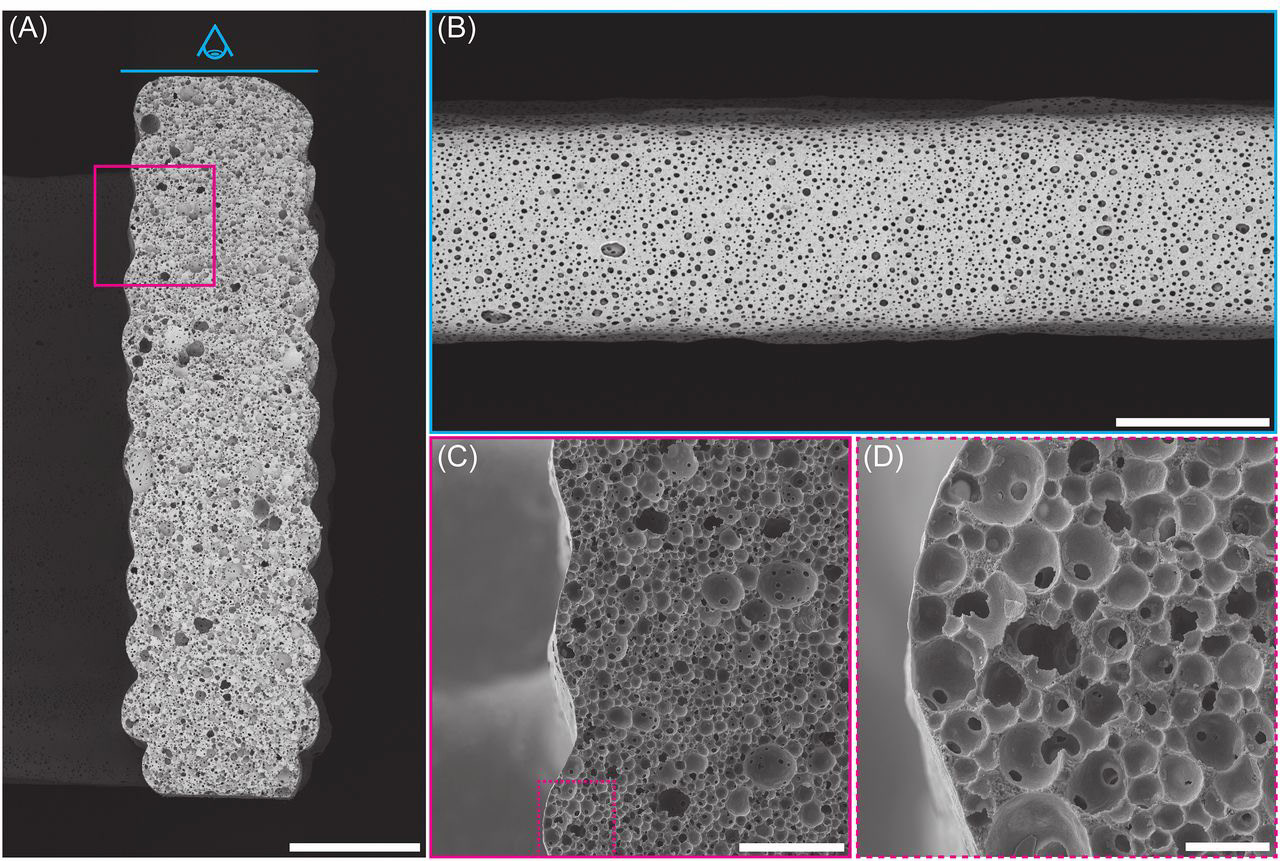

What if we create a Regolith-based material than can be "foamed" with architected bubbles to increase its volume and strength?

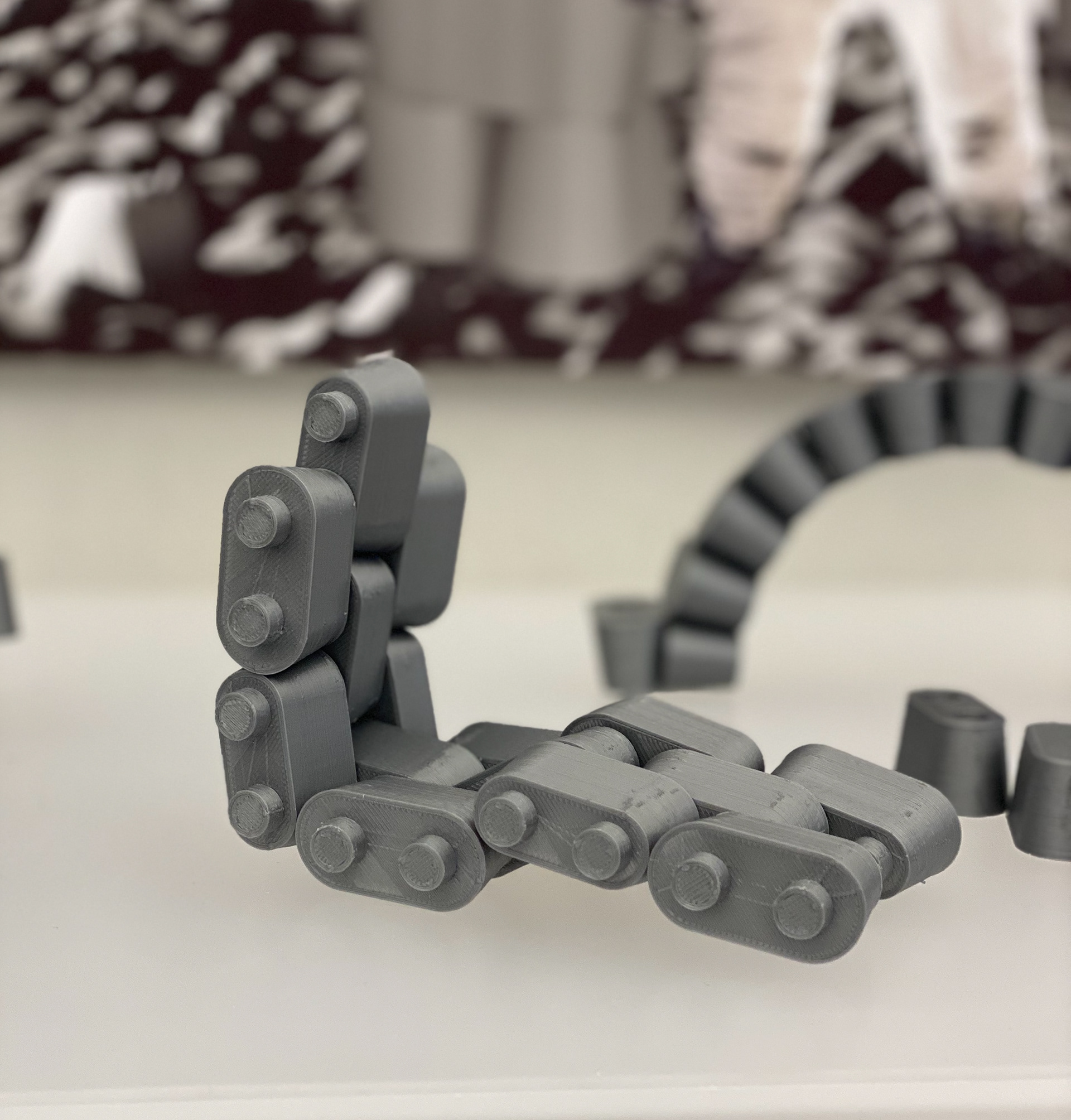

What if we use this novel "Mooncrete" to create versatile construction blocks that can compliment the astronauts on their Lunar missions for shielding, resting, and structural needs?

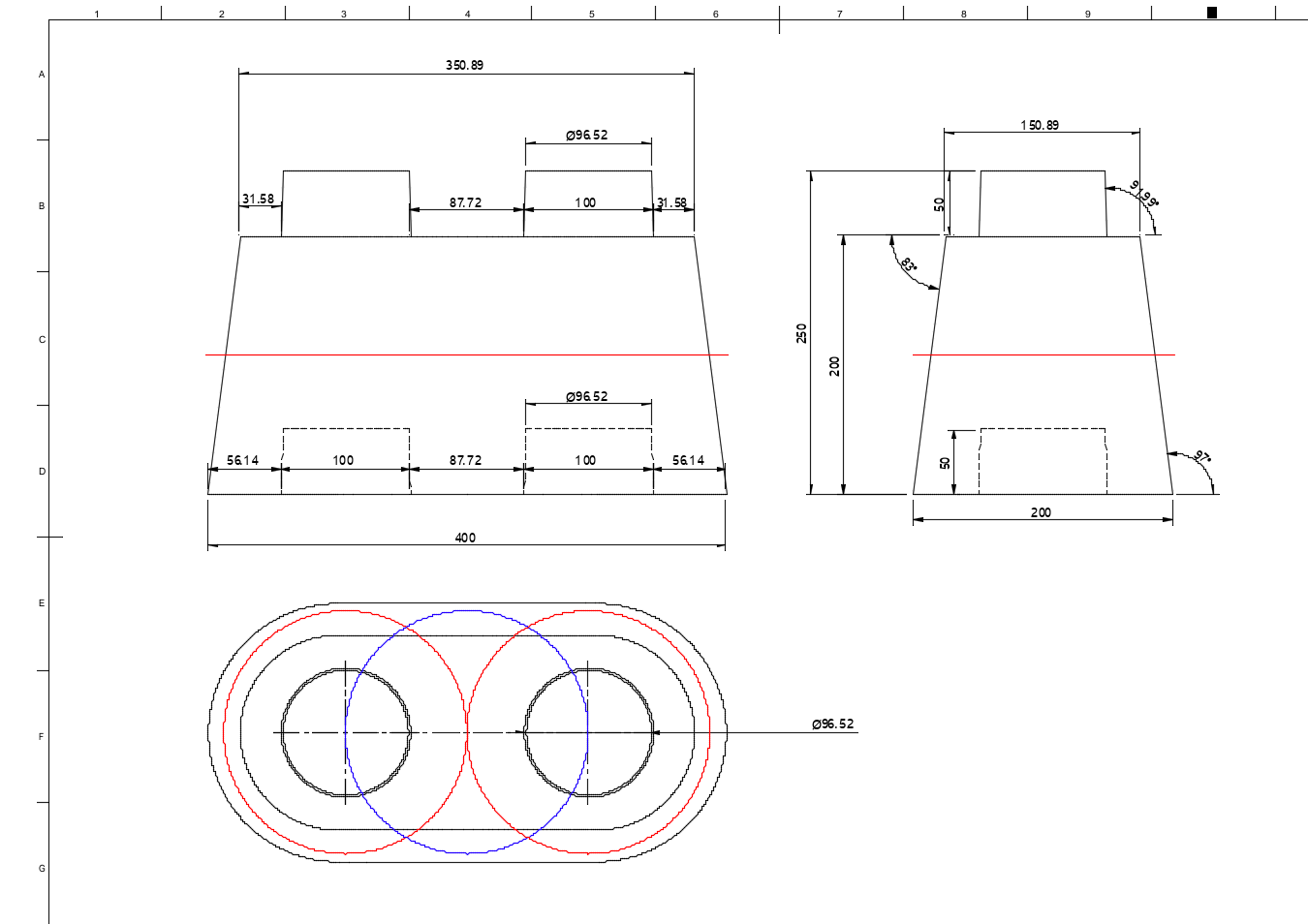

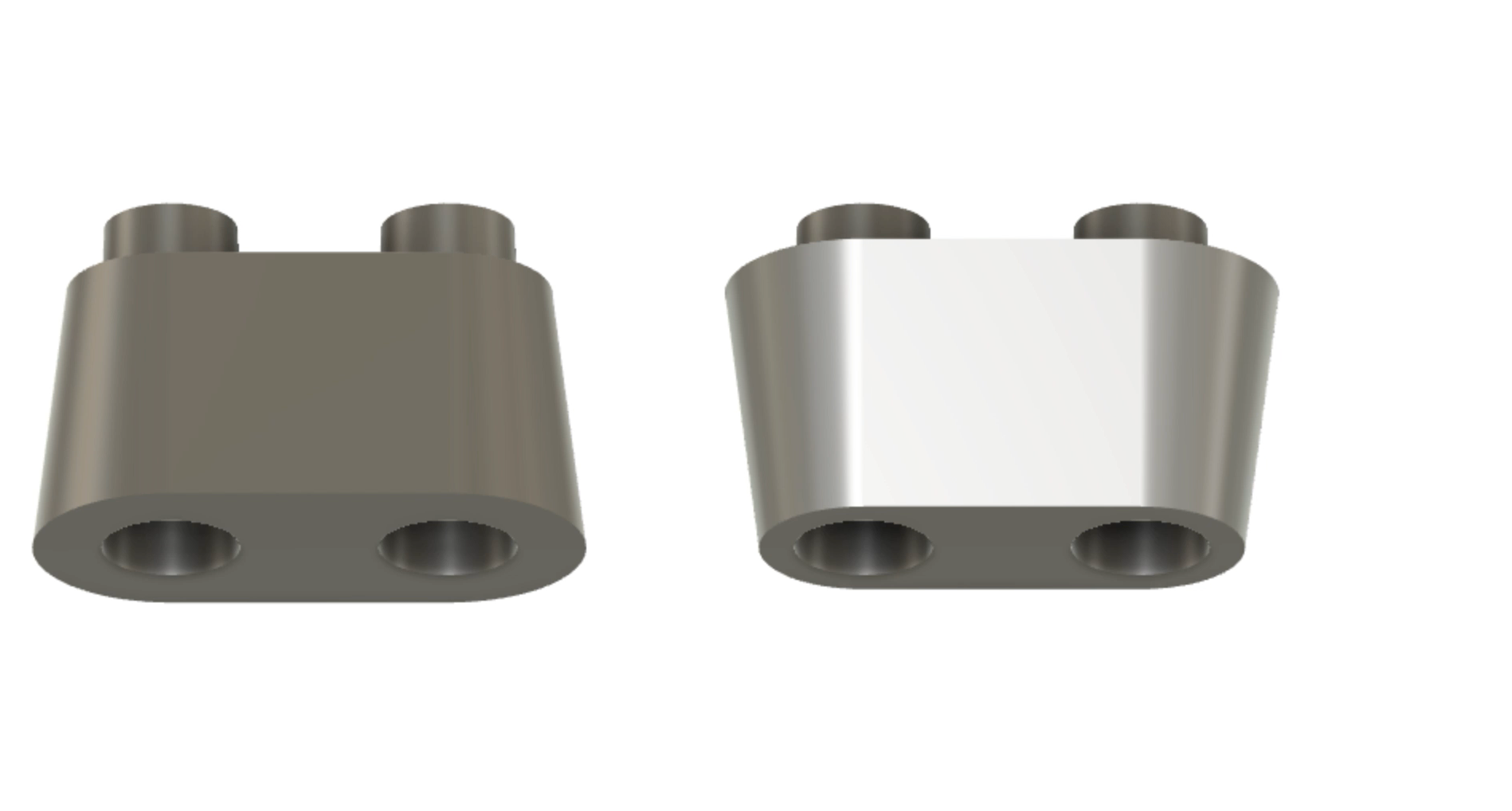

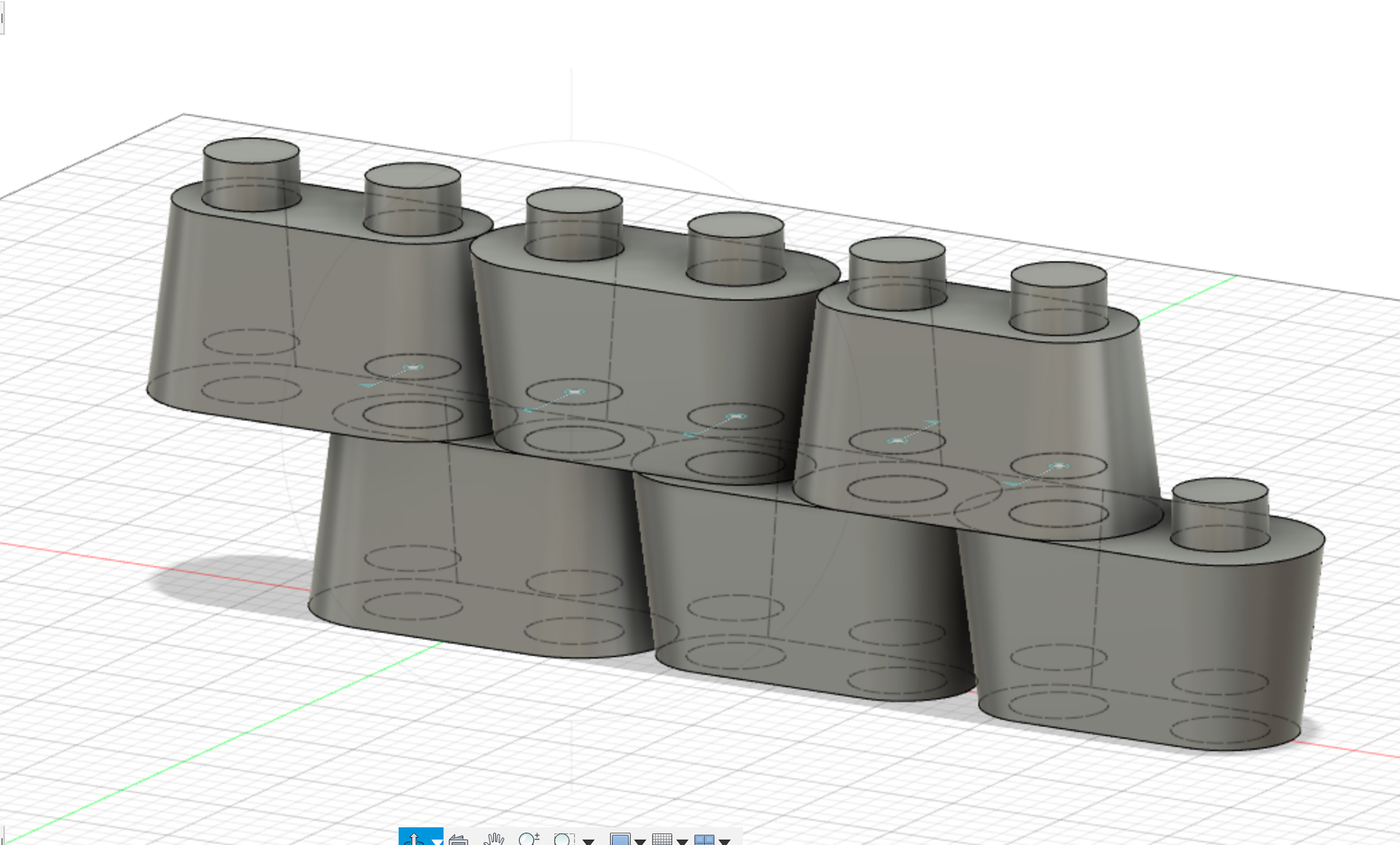

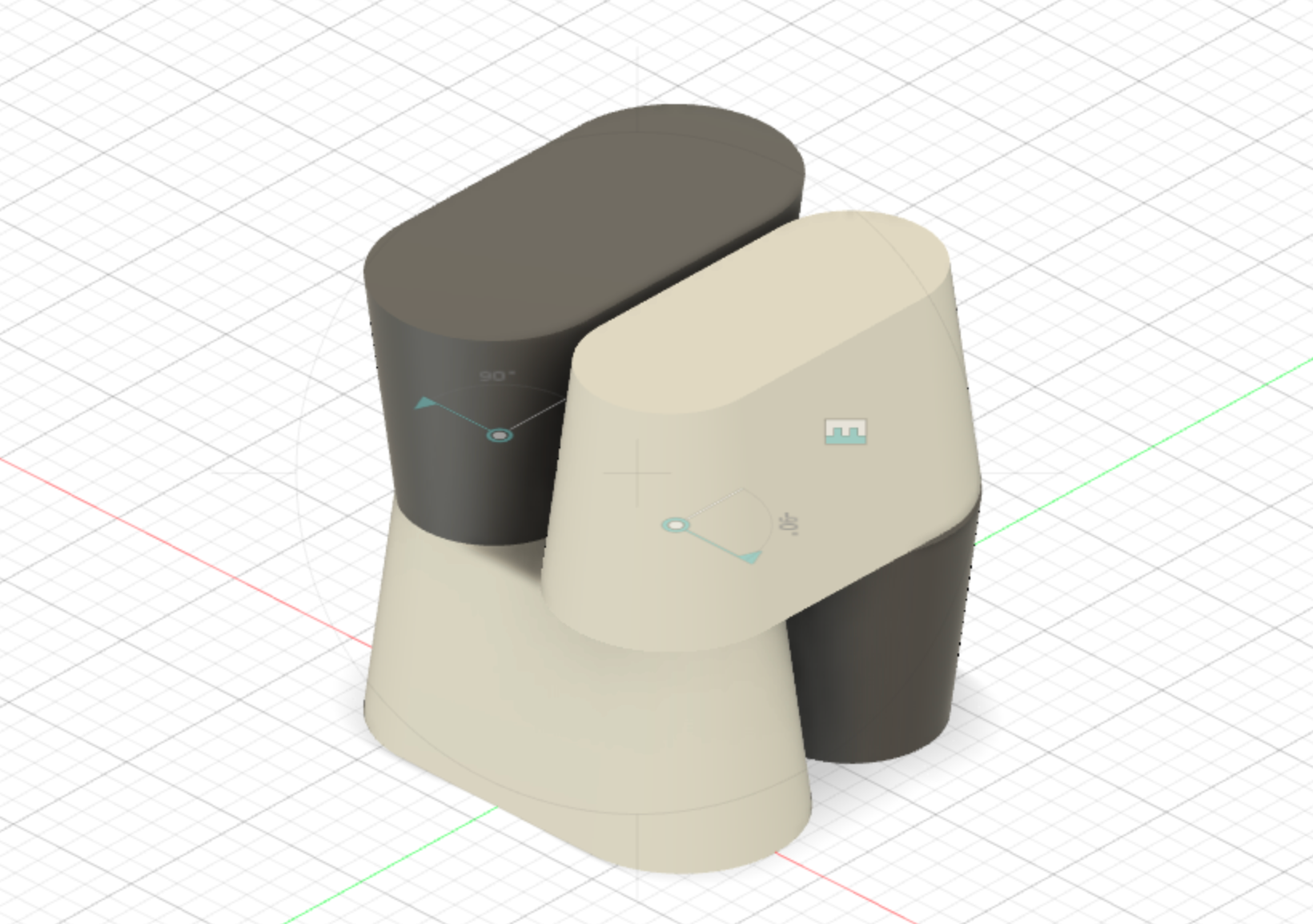

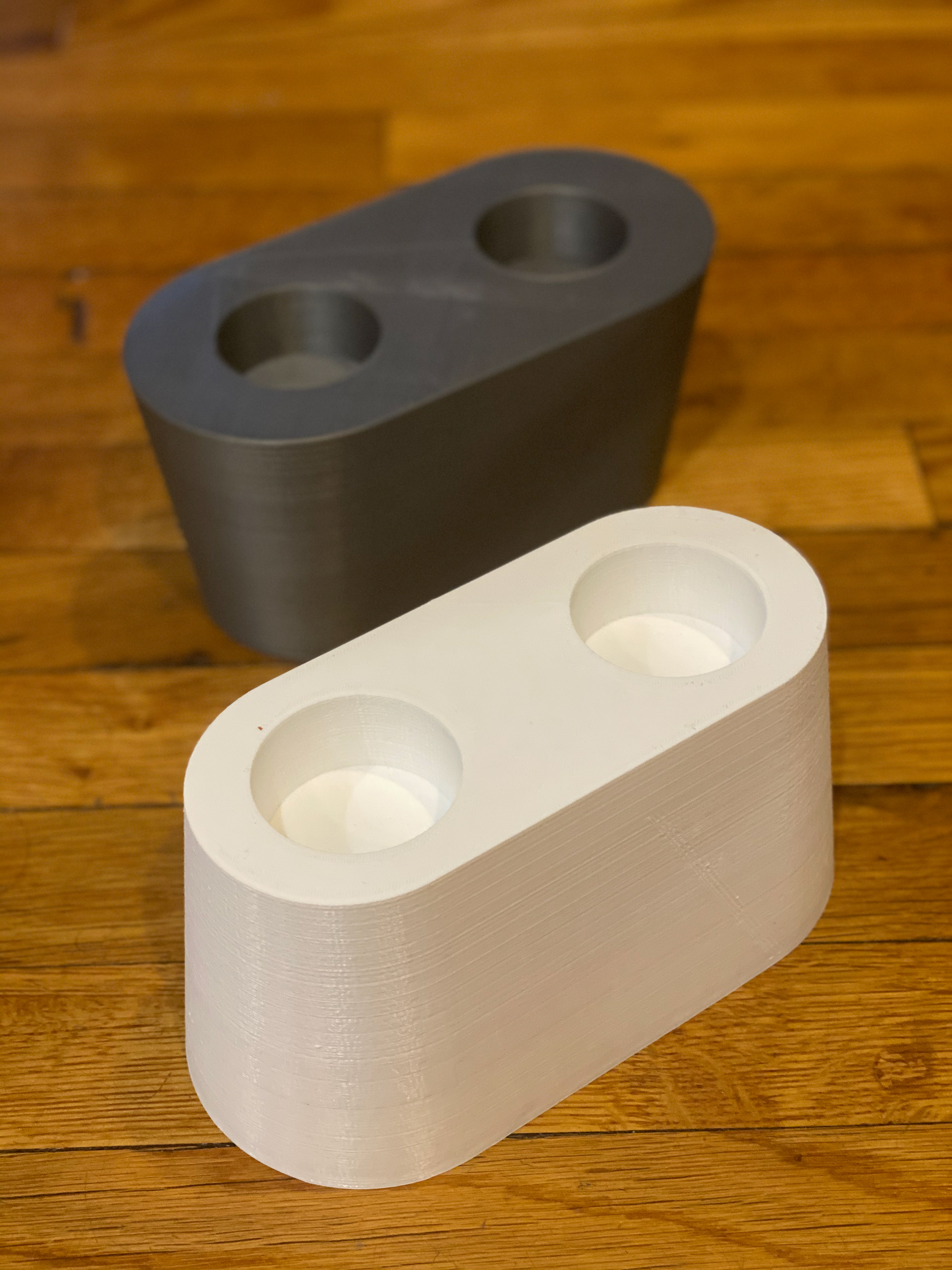

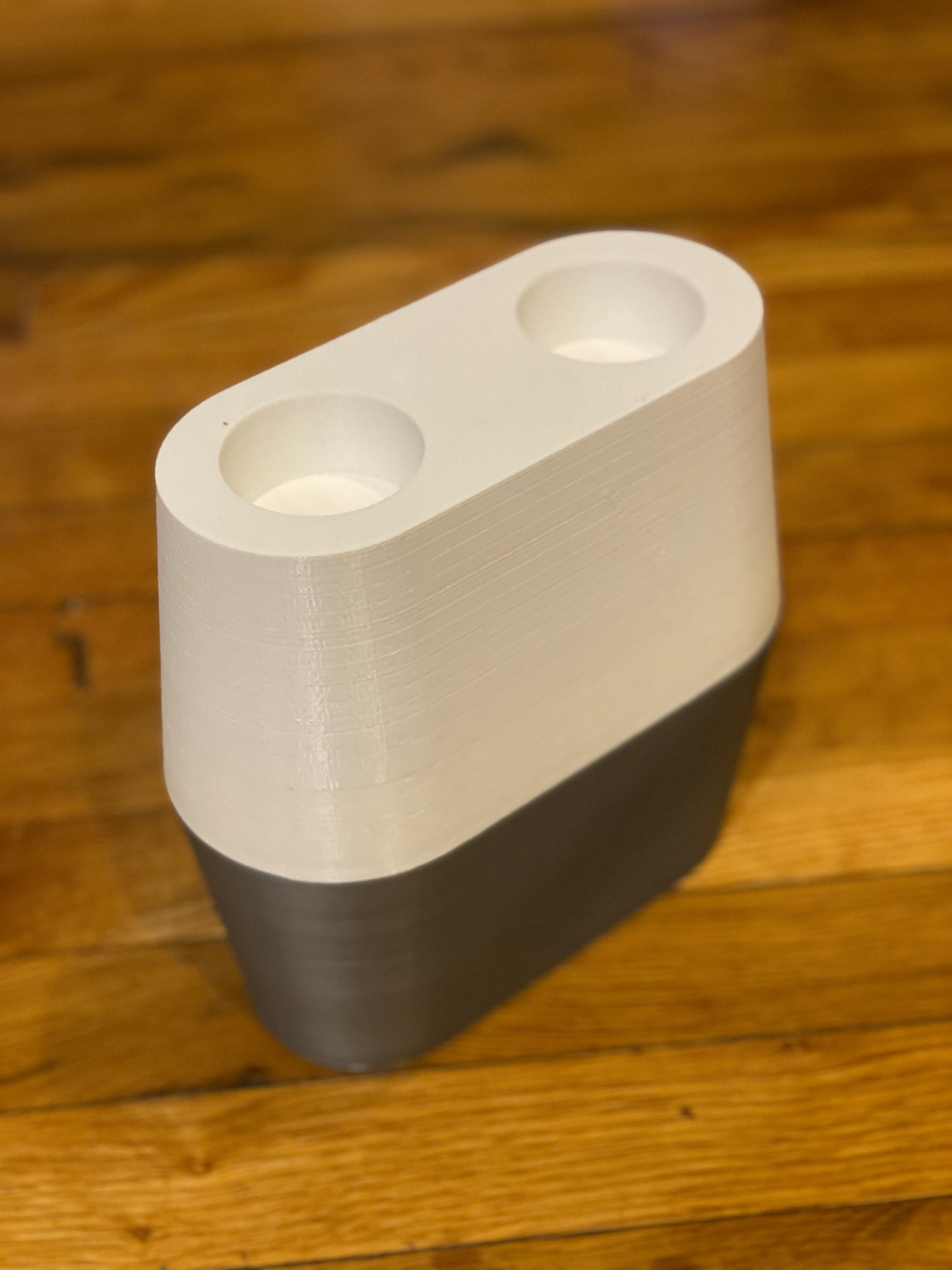

What would the mold look like? Why if we create 4 different shapes with the same mold?

My research was published by the AIAA and presented on the SciTech Forum. If you wish to review the whole thesis, please download the available PDF

https://drive.google.com/file/d/1T0sx3y5_HGXZxvxOE84Qupvwjeroan6k/view?usp=sharing